"How can we design and manufacture furniture for a community common space?"

This project stems from a crazy idea I had a while ago where I'd like to see students use sketching, modelling tools and full sized machinery to make furniture. Now its becoming a reality.

Curriculum

This project is scheduled to take 8 weeks. We are scheduled to finish in the last two weeks of the semester to finish mid June. The outcomes for this project are from DES 1030 (3D Design) and DES 1050 (CAD 1). Essential tools are paper, cardboard, glue, pencils, plywood and Sketchup.

Inspiration

Students started with sketch ideas and seeking inspiration. We created Pinterest accounts with furniture design as the title of one of our boards. Here's mine. Students then spend a few days sketching out ideas for their furniture. By the end of the 3 days most students had made up their minds as to what kind of furniture they were going to make. Students were put into design teams to present their sketches and have discussions about their design, inspiration and seek input from others. We call this getting a 'reality check', and it happens after every step in the design process.

Students started with sketch ideas and seeking inspiration. We created Pinterest accounts with furniture design as the title of one of our boards. Here's mine. Students then spend a few days sketching out ideas for their furniture. By the end of the 3 days most students had made up their minds as to what kind of furniture they were going to make. Students were put into design teams to present their sketches and have discussions about their design, inspiration and seek input from others. We call this getting a 'reality check', and it happens after every step in the design process. After learning about the CNC machine we had bought, I had to narrow the focus of our essential question. Making furniture with a CNC machine in 8 weeks is not easy task, and if we were going to get to making REAL chairs and tables, I had to guide them further. The style of furniture we were now pursuing for inspiration was flat-pack furniture. Students researched what this term meant and investigated how IKEA is one of the innovators of flat-pack furniture. I also wanted them to see that flat-pack furniture didn't necessarily mean we all had to make our pieces the same style.

We found inspiration is James McBennet's Fabsie project which I had backed on Kickstarter earlier in the year. Among others, James is working on a unique method of manufacturing that is more efficient, and is environmentally friendly because instead of having a large warehouse and shipping goods long distances around the world, you share digital design files with local manufacturing experts in close proximity to the end consumer. These local experts use the design specs for the CNC machines and manufacture a piece of furniture from it. The shipping costs are lower, less jet fuel, and gas used to deliver it and it supports local businesses! Plus there is no overhead to maintain in a big warehouse. The files are often only a few dozen kb in size. It's a great model!

So we narrowed our focus:

"How can we design and manufacture flat pack furniture for a community common space?"

Build to Think

This is becoming a bit of a buzz word in my class but it is a really important step. Students used scrap cardboard to make an early prototype chair. It helps bring their 2D sketch into something tangible. Each student presented their cardboard model. Peers would comment on their models. "I really like" and "Have you thought about" are our two guiding phrases for feedback.

Research, research and more research.

This project had so many opportunities for students to investigate. We started with inspiration and ended up talking about design standards. Students guided the learning as we went along. We spend 3 whole days on design standards and measuring furniture in our school. It was important to let the students find out what they needed to know and guide them when they were getting stuck or hung up on things. By the end of the project we all knew the design standards for chairs and tables and students were using this in their everyday conversations.

This project had so many opportunities for students to investigate. We started with inspiration and ended up talking about design standards. Students guided the learning as we went along. We spend 3 whole days on design standards and measuring furniture in our school. It was important to let the students find out what they needed to know and guide them when they were getting stuck or hung up on things. By the end of the project we all knew the design standards for chairs and tables and students were using this in their everyday conversations.Reality Checks

We've had a lot of them. Reality checks have taken many forms during this project. Some have been what I'd call 'formal'. These are teacher directed reflections that students were required to complete and blog about. One other form of reality was also teacher directed but student facilitated. I would pose questions (such as asking students to check seat heights against the design standards) and students would go to each other's workstations to have conversations about their designs.

Prototyping

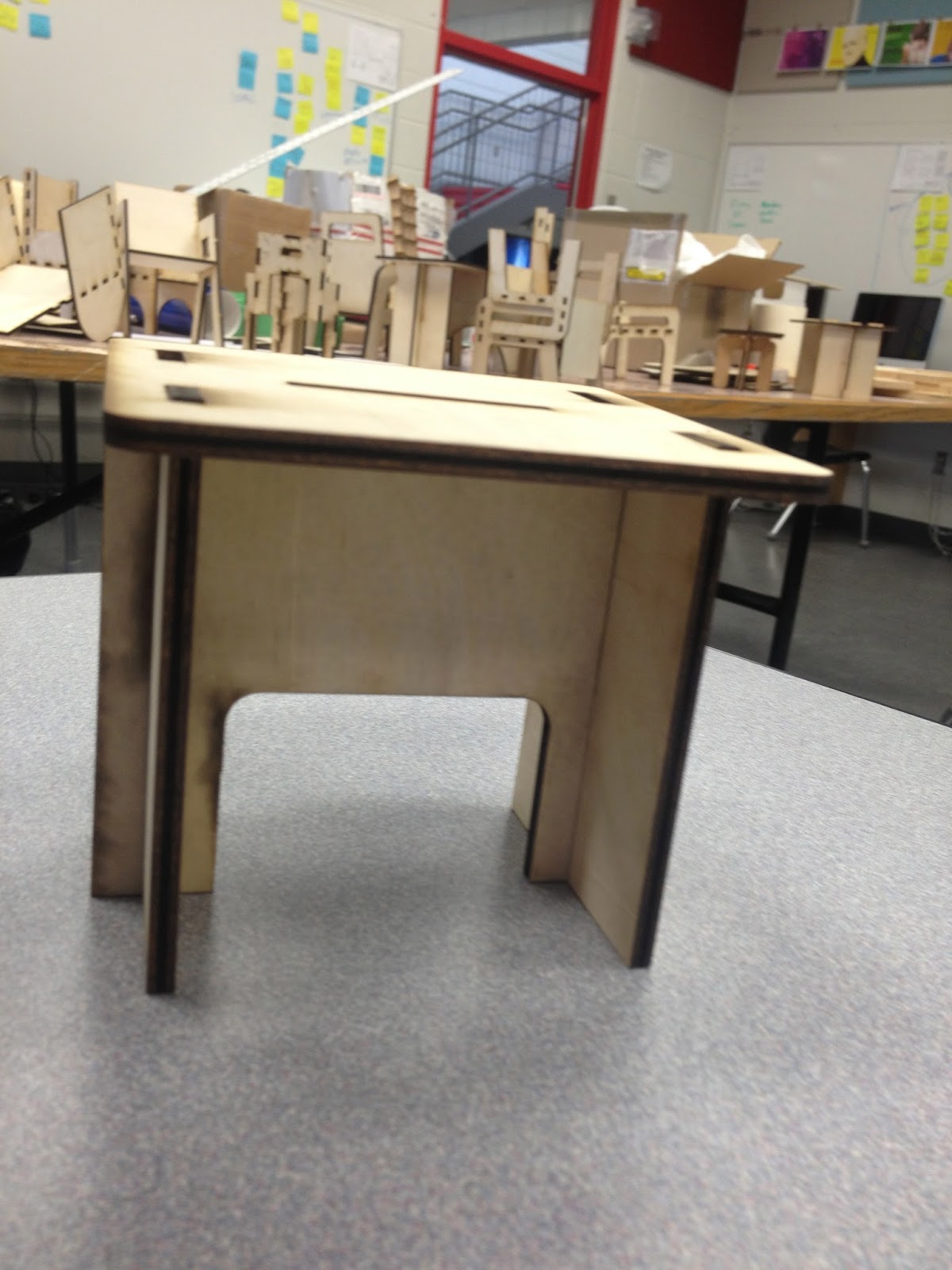

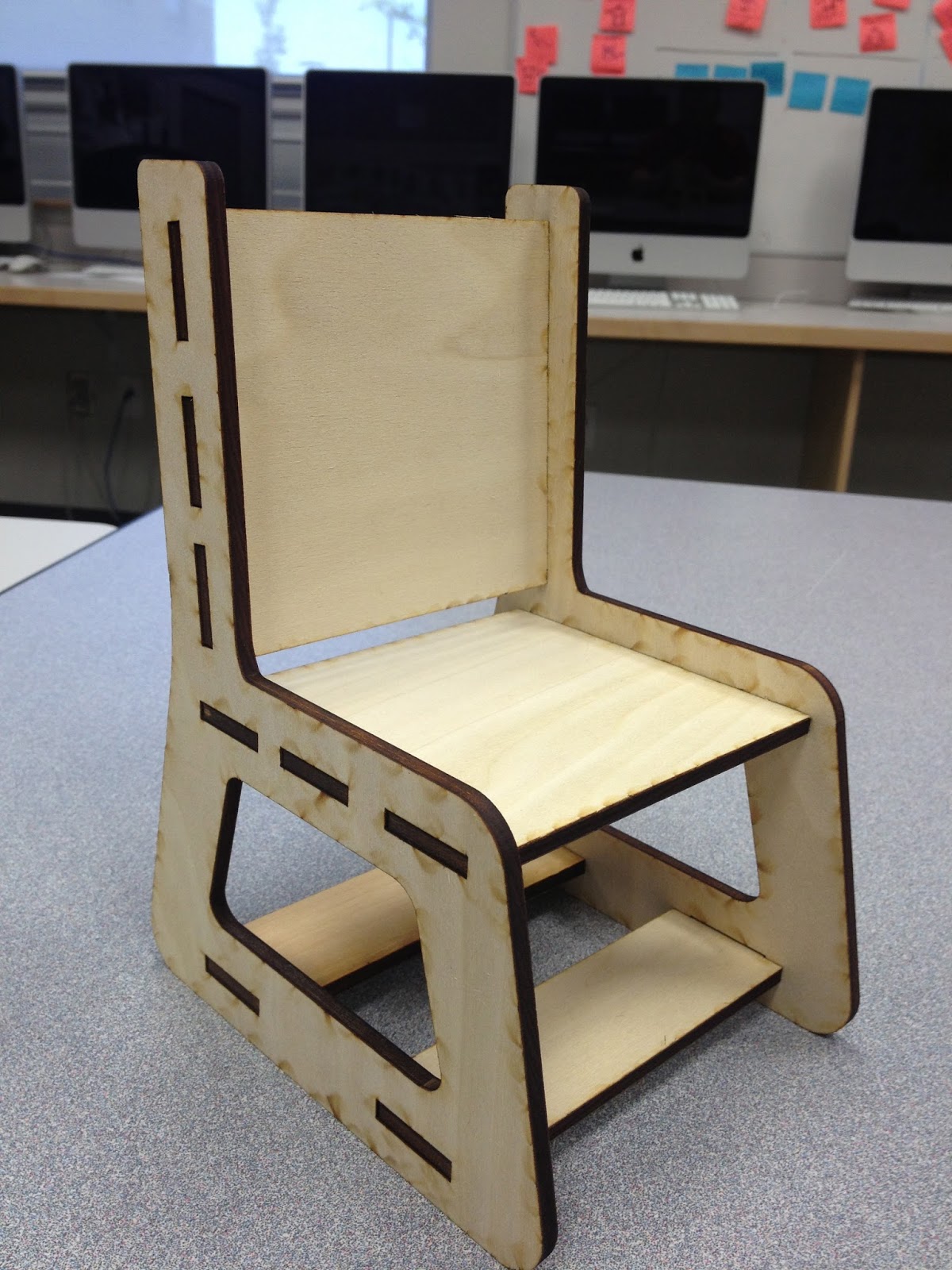

PrototypingAfter students made physical models they spend at least a week just on modelling in Sketchup. I gave an introductory lesson one class on sketchup, and introduced another research topic which was common joinery techniques in flat pack furniture. Cardboard models turned into laser cut models with thin birch plywood. My classroom began to look like a doll furniture factory. Discussions of strength, form and function where happening everywhere.

I'm learning about manufacturing and prototyping right along side of the students. I even started to sketch out my own chair design and made a couple lasercut models. Seeing my idea go from a sketch into a model is really neat.

Update!

After 8 weeks and several phases of prototyping including full size prototypes from lower grade plywood, the project was completed! We used our Shopbot CNC machine extensively and lived in the shop for the last 2 weeks of the project. There was a ton of finishing work to do!

Overall there were 6 pieces of furniture that were produced in teams. We had a celebration and grand reveal of the furniture at the Cold Lake Energy Centre attached to our school with several board members, management from the recreation centre, and a reporter from the local newspaper who did a pretty good job of telling the story.

The most gratifying aspect of the project for me and my students is that these pieces of furniture will be used for many years to come.

Content is the greatest source for marketing your blog, thoughts, good or bad times. Your post is fabulous and very meaningful.

ReplyDeleteMonster Race 3d Game

This is awesome! This approach of using local businesses as your source for materials, and having the finished product be used by the community, has to be emulated. The process looked very thorough, and I like that even you learned something from this project. You and your students should be very proud of what you have accomplished, and I hope everybody involved picked up a thing or two from the activity. Thanks for sharing!

ReplyDeleteDeborah Williams @ Choice Career College

It's Impressive Knowledge for my home furniture. It seems like a practical and cost-effective solution.

ReplyDeleteFurniture Pack

I was searching for a unique headboard for my bedroom, and Multiwood AE was able to bring my vision to life. They used high-quality materials and exquisite craftsmanship to create a truly one-of-a-kind piece. Their team was very responsive and accommodating throughout the entire process. I am extremely satisfied with the final product and would highly recommend their services to anyone looking for custom made furniture in Dubai.

ReplyDelete"This post really resonated with me. Thank you for putting it so beautifully."

ReplyDeleteConsole Tables

This is good post, Thank you foe this wonderful blog

ReplyDeleteFolding Beds

Discover why budget-friendly RTA kitchen cabinets are the smart choice for stylish kitchen makeovers.

ReplyDelete